New, advanced materials can sometimes be challenging to weld with conventional equipment. Differences in material compositions, strengths, hardnesses, and new coatings can increase demand on equipment and contribute to subpar results. The industry needs options—and today, manufacturers have an additional one that uses industrially recognized and accepted MFDC equipment while providing enhanced performance.

CPRW offers:

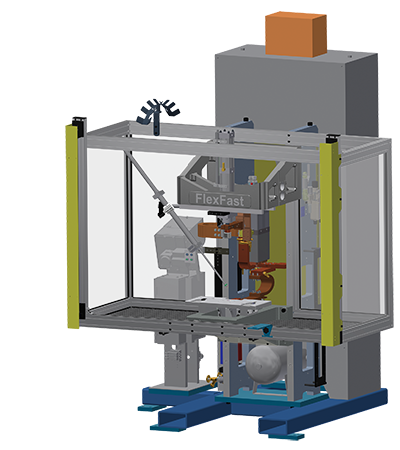

The following products can all be outfitted with CPRW systems:

For more information, please Contact Us.