Robust Construction and Modular Flexibility

This collection of weld gun designs reflects CenterLine’s cumulative experience in resistance welding and provides manufacturers with one of the most practical and reliable weld gun products available today.

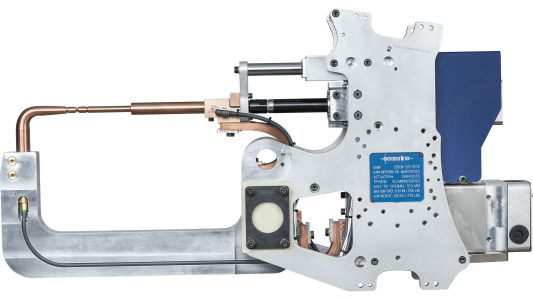

Gun base-bodies for both the C and Pinch style guns are designed for heavy duty cycles and support large throat geometries selected from our standard arm and adapter library. The FlexGun™ 3 has protective covers that are quick and easy to remove, allowing access for maintenance.

Our weld gun designers are known for creating custom weld guns for challenging workpiece and tooling geometries. We insource all our weld gun manufacturing to control the entire process and ensure a quality, long-lasting weld gun.

The FlexGun™ 3 is also available as part of a patented PedTec™ pedestal mounted solution, integrated with our KapTec™ Weld Cap Maintenance station. PedTec™ Integrated Solutions are pre-engineered, tested, and supplied complete, with 3D models and documentation for easy integration. These configured products save design, build, commissioning time, and floor space.

Key Features