Cap Maintenance Systems

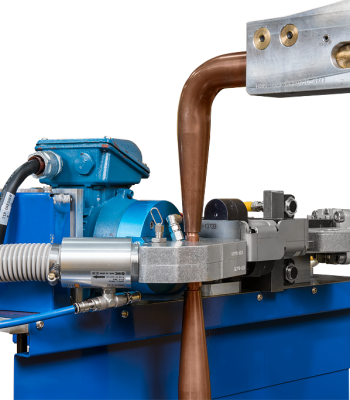

CenterLine is the only manufacturer of a self-contained, fully automated cap dressing and cap changer unit for Single or Dual Pedestal mounted weld guns, that do not require a robot. KapTec™ offers solutions for all your weld cap servicing needs including robot carried weld guns to Single and Dual Pedestal mounted weld guns.

Compared to manual cap changes, KapTec™ offers:

Standard Features

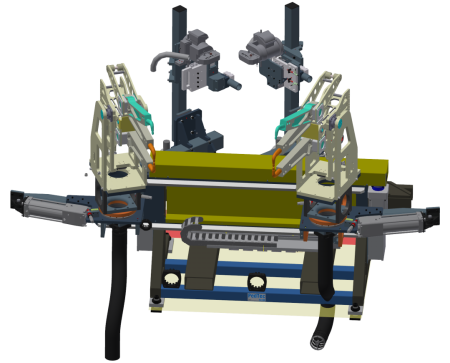

KapTec™ Integration with PedTec™ Solutions

PedTec™ Solutions are pre-engineered, supplied complete, and fully tested, with 3D models and documentation for easy integration. These configured products save on design, build, and commissioning time, as well as floor space.

PedTec ™ pedestal-mounted weld guns are available as Single and Dual weld gun solutions. They accommodate various gun styles which can be mounted with different heights, angles, and orientations to meet your process requirements.

Pedestal-mounted FlexGun™ 3 and FlexGun™ Ultra weld guns, when integrated with KapTec™ weld cap maintenance, offer ready-to-integrate solutions.

CenterLine is the only manufacturer of both robot-mounted weld guns and patented pedestal-mounted weld guns with integrated Weld Cap Maintenance Stations to increase welds/minute, cell uptime, and weld cap life.