FlexGun™ Ultra & Ultra HC (High Capacity)

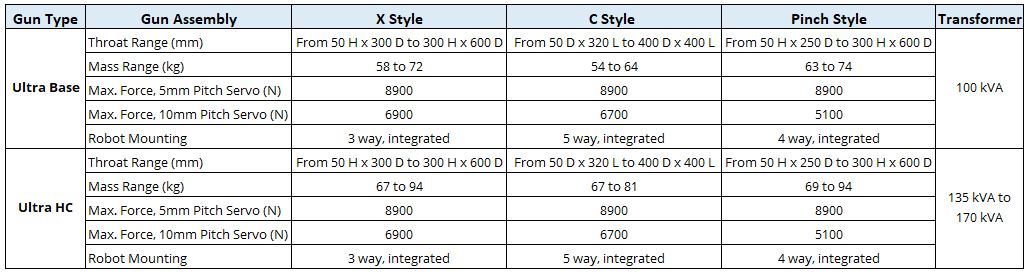

The FlexGun™ Ultra and Ultra HC (High Capacity) are lightweight weld guns that are part of CenterLine’s FlexGun™ Product Family. These are ideal for use on robot models with payloads starting at 80 kg and for applications requiring 2.5 to 8.9 kN of weld force.

With integrated robot mounting, superior strength-to-weight ratio construction, compact size, and true symmetrical design, the FlexGun™ is ideal for high-density manufacturing needs.

Key Features