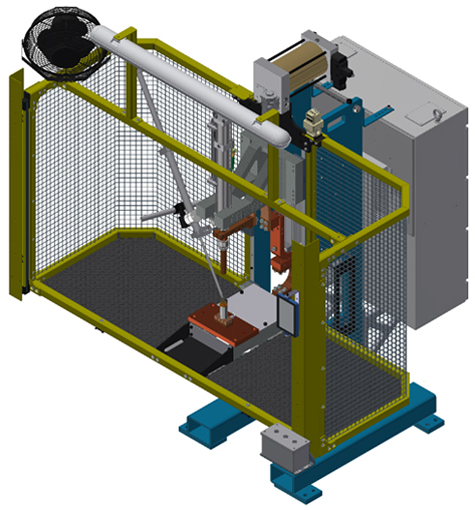

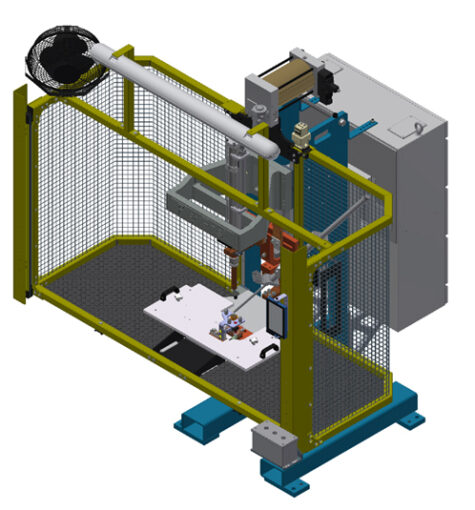

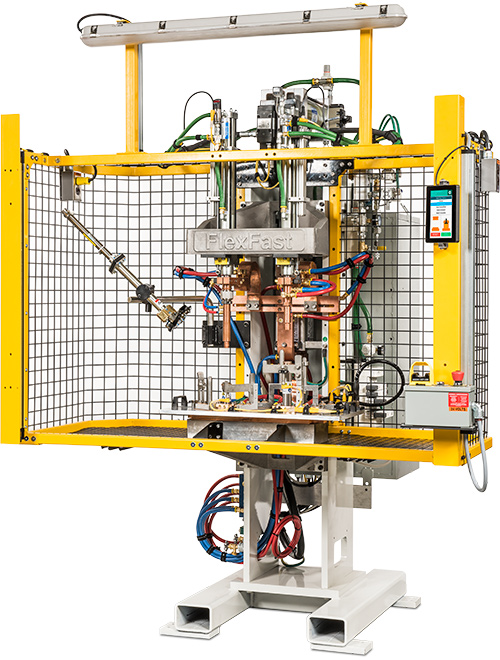

FlexFast™ CLCS

The CenterLine FlexFast™ CLCS (CenterLine Control Solution) configured stationary welder is a compact, versatile, welding machine designed for production fastener welding applications. This design includes many standard features that ensure the FlexFast™ CLCS produces consistent weld quality, is easily operated, and has minimal maintenance requirements.

The FlexFast™ CLCS offers:

CLCS HMI Features

FlexFast™ CLCS Models